When Xiao Wang inspects the industrial site, he can always see a type of steel pipe material with unique appearance characteristics, which is a protruding pipe fitting, and he doesn't know what to call it. Later, science popularization learned by themselves that it was originally called butt welding flange. This type of appliance seems to bring many benefits to industrial work, so what is an industrial butt welding flange?

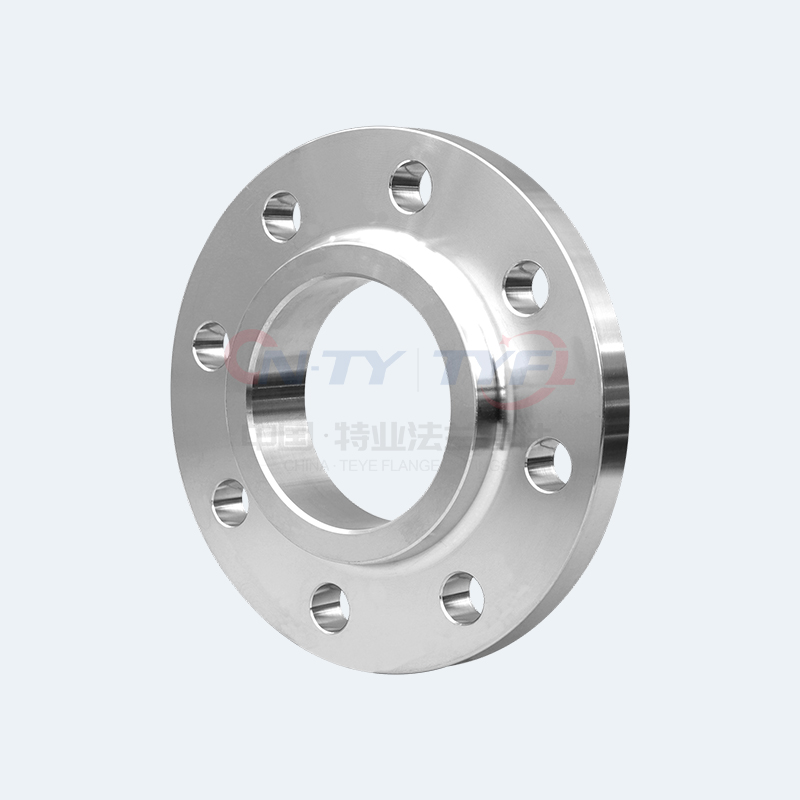

Butt welded flange is a pipeline appliance that refers to a flange with a neck, which has a transition part of a circular pipe and is butt welded to the pipeline. Butt welded flanges have the characteristics of being resistant to deformation, good sealing performance, and wide application. They have corresponding rigidity and elasticity requirements, reasonable thinning and transition of butt welding, and the welded joints are far away from the joint surface, with no welding temperature deformation on the joint surface.

Butt welded flanges have the characteristics of being less prone to deformation and having good sealing performance, which are widely used and have corresponding rigidity and elasticity requirements. Reasonable thinning and transition of butt welding can improve performance! Of course, the welded joint is far away from the joint surface, and the surface of the welded joint is not easily affected by welding temperature deformation. It needs to be more suitable for high-pressure or high-temperature, high-pressure and low-temperature pipelines. It is usually used to connect pipelines and valves with PN greater than 2.5MPa. It is also used for expensive materials, flammable and explosive transportation.

What is the connection form?

Connection form: single sided welding, double sided nut connection.

The product features beautiful appearance, smooth surface, acid and alkali resistance, corrosion resistance, and strong texture.

The production process involves cutting in an oxygen furnace, whole forging, or finished product forging and cutting.

Processing method: high-precision CNC lathe turning, CNC rocker arm drilling.

By skillfully using different types of flanges in situ, industrial efficiency can be improved. Butt welded flanges can effectively assist industrial workers in solving connections and improving sealing issues.